Tools

Download our free business value calculator to determine the potential benefits of your project

Device partner

Product description

District heating pipelines can be insulated by a vacuum. These pipelines have a very high insulation coefficient. This is only the case when there is a vacuum. Due to wear and tear the vacuum can disappear. As a result remote monitoring of the vacuum is essential to keep the pipelines in optimal condition. This device continuously monitors the vacuum in real-time and sends an alarm in case the vacuum disappears.

Customer use case

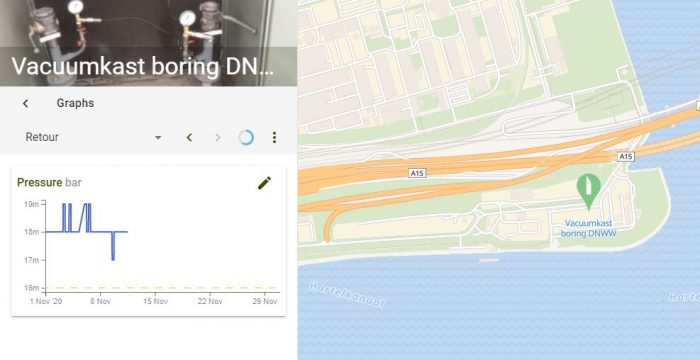

The distribution grid of District Heating Rotterdam has a total length of 29 km. Some parts of the grid consist of SiS (steel in steel) pipes. Between the outer and inner pipe a vacuum is maintained for optimal insulation to avoid heat loss. Inspecting these components regularly requires significant time from already scarce technical resources and between manual inspections there was no information available about asset condition or possible failures. The challenge was to provide District Heating Rotterdam with real-time monitoring of their distribution grid in order to make maintenance processes more efficient and to get immediate failure notifications when something is wrong. To this end, multiple vacuum sensors have been installed which successfully monitor the vacuum.

“Withthegrid’s solution gives us a real-time insight into the status of the vacuum in our steel-in-steel district heating pipes, ensuring optimal insulation and energy preservation.”

Remco Roos – Asset manager District Heating Company Rotterdam

Software functionality

The online Withthegrid application is designed to give the user a complete overview of asset performance. You can view historic performance, set thresholds and alarms and enrich the overview with manual measurements from the field.

Deep integration with this vacuum remote monitor allows you to:

- Automatically detect anomalies

- Have a real-time status of your pipelines

- Monitor follow-up actions for your personnel

Device specification

| Product code | RTU-Vacuum |

| Power supply | Battery |

| Communication protocol | NB-IoT |

| Remote adjustable measuring frequency | 1x per 5 mins to 1x per week |

| Ambient measurements | Temperature and humidity |

| Inputs | 2X 0-10V |

| IP-rating | 67 |