Why leak detection sensors?

- Direct detection of excavation damage

- Continuous monitoring of pipes during warranty period (and beyond)

- Savings of operational man-hours

- Reduced administrative burden (direct and automatic historical measurement reports incl. audit trail)

- Extended lifetime of pipes

- Less serious damages and lower damage costs

Specifications

Sensor

- Insulation resistance (Range: 5k Ohm – 1G Ohm, Accuracy: ± 10% + 0.1% of range)

- Loop resistance (Range: 0-500 Ohm, Accuracy: ± 2% + 0.1% of range)

- Voltage: 10V (Imax 10mA) – 250V DC (Imax 4mA)

- IP-rating: 65

- Communication protocol: GPRS or NB-IoT

- Remote adjustment of measurement frequency (1X/minute to 1X/week)

- Remote pausing of measurements during works

- Does not need to be physically decoupled during welding

Number of measurement loops:

- 4 (for 1- or 2-wire measurement systems)

- 8 (for 4-wire measurement systems)

Power:

- Mains power (230V)

- Battery (without replacement 6 years with 4X/day measurement)

According to the norms:

- CE

- EN 14419

- EN 55011

- EN 61000-6

Installation proces:

- Less than 15 minutes installation time per sensor

- Can be installed by field mechanic (no extra certifications required)

- Automatically coupled to asset and GIS-systems via online platform

Software platform environment

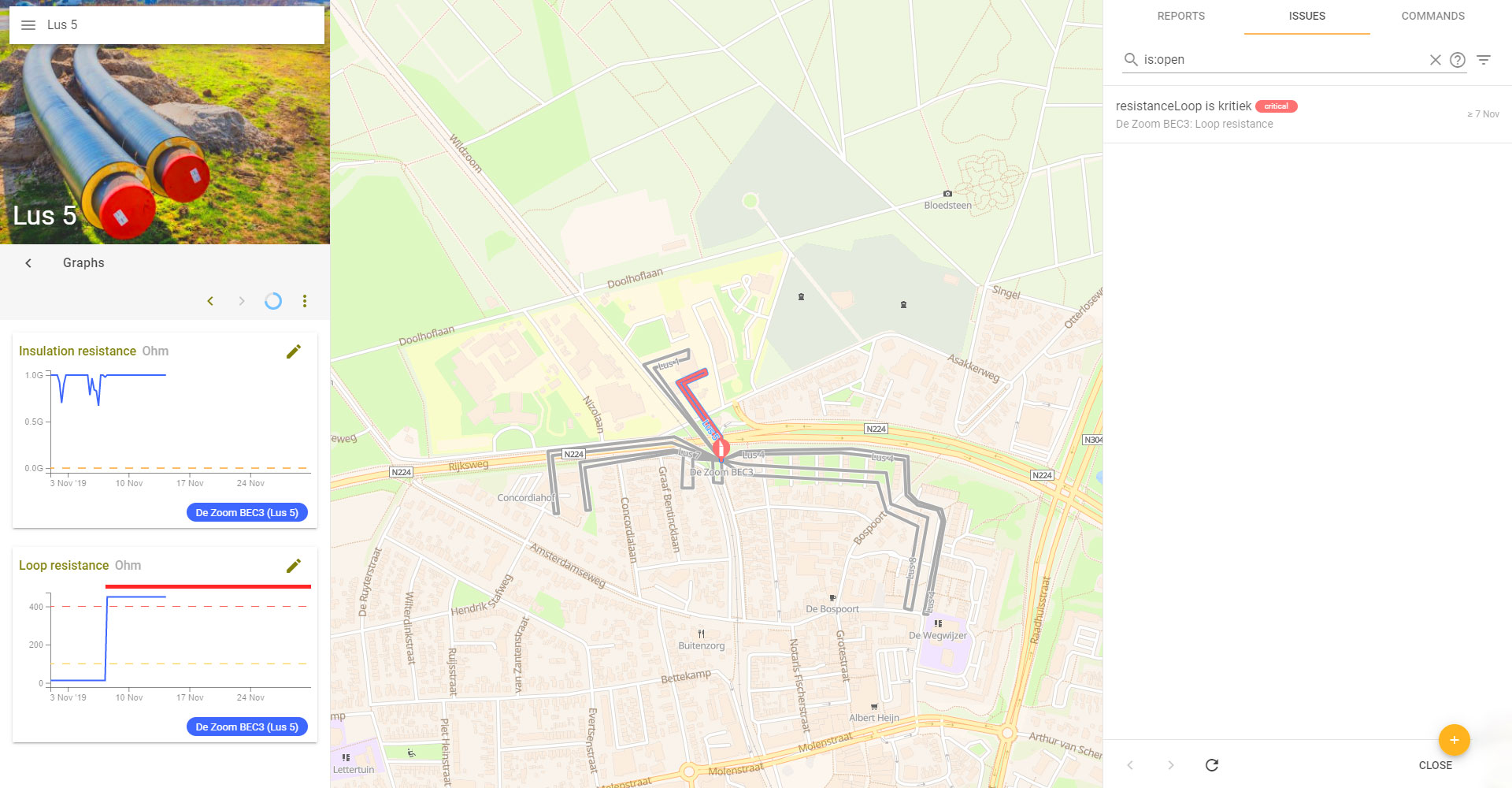

- Graphic representation of pipes and measured insulation and loop resistances

- Overview of actual and all historical measurement data

- Setting of thresholds and receiving alarms via e-mail

- Advanced user / access matrix with specific roles for measurement specialist and asset manager

- Full audit trail (including changes to measurement frequency and thresholds)

- Report functionality

- Annotation functionality (explain measurement anomalies)

- Data export functionality

- Link with customer systems via API or OPC UA connection

Security

- Complete end-to-end data encryption (CoAP over DTLS)

- Data processing and storage in line with ISO 27018 and GDPR legislation

Who preceded you?