Cathodic Protection: a brief introduction and why IoT is important

There lies a great deal of capital in the ground in the form of steel pipes. These pipes transport water, gases, and liquids, and are part of vital infrastructure. Cathodic protection can extend the service life of pipes to more than 100 years. Naturally, this is the case when it protects them properly.

This article explains what cathodic protection is and how you can realize even more value from steel pipes through remote monitoring sensors and IoT.

What is cathodic protection?

Cathodic protection is the supply of direct current to steel objects in the soil or water. Moreover, it is a way of protecting steel objects from corrosion. The potential is lowered by the current on the steel pipes. As a result, this reduced potential slows down the corrosion process. As commonly known, cathodic protection protects almost all steel pipes in the ground or water. For further protection, pipes also have a coating that serves as a primary protective agent. Cathodic protection has two variants:

Sacrificial

Here, a piece of metal, which is a base metal, is connected to the pipe which is to be protected. The piece of metal forms the anode. It is usually made of zinc, aluminum, or magnesium. The coupling creates a protective current for the steel object. The anode is, as it were, sacrificed for the protection of the object.

Impressed current

A second method is to supply a protective current with an external power source. This is an Impressed Current Cathodic Protection system (ICCP). The external power source is usually provided by a rectifier in combination with a base metal. However, which anode is best to use depends on various factors. A CP specialist can determine that best.

How to maintain cathodic protection?

Naturally, maintenance is very important in order to maintain the cathodic protection in good condition. The sacrificial anode or rectifier must still be able to adequately protect the object. In addition, the protection must be present over the complete object. To check this, inspections need to take place. When this is carried out manually, the frequency must be met as stated in the standard EN 12954. This means that checking rectifiers ought to happen at least every 4X years and drainages at least every month. In addition, check at measuring poles need to happen every 3 years (and parts thereof every year).

The CP standard states that when IoT sensors (telemetry) are present, deviation from the mandatory inspection frequency can happen. It is therefore valuable to monitor cathodic protection by means of telemetry.

What is telemetry?

Telemetry, or remote control, is the remote monitoring of objects (for example pipelines) with the help of sensors. The sensors are connected to an asset. In addition, they periodically send their encrypted measurement data to an online environment. A digital map shows which pipe sections are functioning well or which require attention. In case of a malfunction, the right person will immediately receive a message. The dashboard will then show which actions need to be taken. After implementation, these actions can be analyzed.

Why remote control?

The main advantage of remote control of cathodic protection is to be able to detect faults more quickly. This can be due to a malfunctioning rectifier, measuring wires not connected after works in the field, or unexpected excavation damage. Due to malfunctions getting resolved more quickly, the life of the assets is extended. Technicians can be deployed efficiently using the current status of the CP in the digital dashboard. This usually means significant savings in man-hours. This also indicates that fewer vehicle movements take place, which results in lower CO2 emissions.

Monitoring cathodic protection with Withthegrid

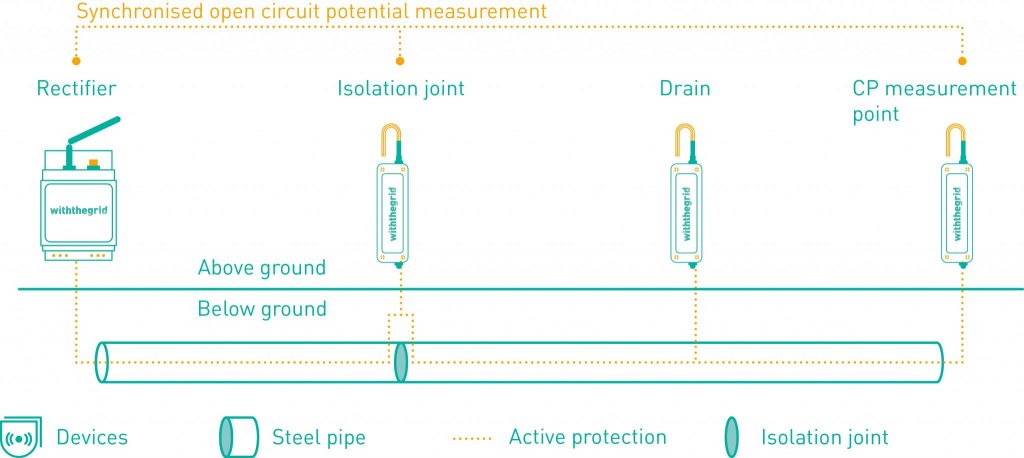

Withthegrid sensors monitor the cathodic protection on steel pipes. The sensors have a connection with the rectifier and at the various measuring points on the line. Both the voltage (DC + AC) and the current (DC + AC) are measured in accordance with EN 13509. A coupon measurement is also possible to measure the IR-Free (in accordance with EN18086). The data is then sent in an encrypted manner to an online environment. In this way, the entire CP system is visible. When you switch the rectifier, it can also carry out off-potential measurements or to perform work on the grid.

Which cathodic protection systems does Withthegrid support?

The Withthegrid solution is applicable to any cathodic protection system:

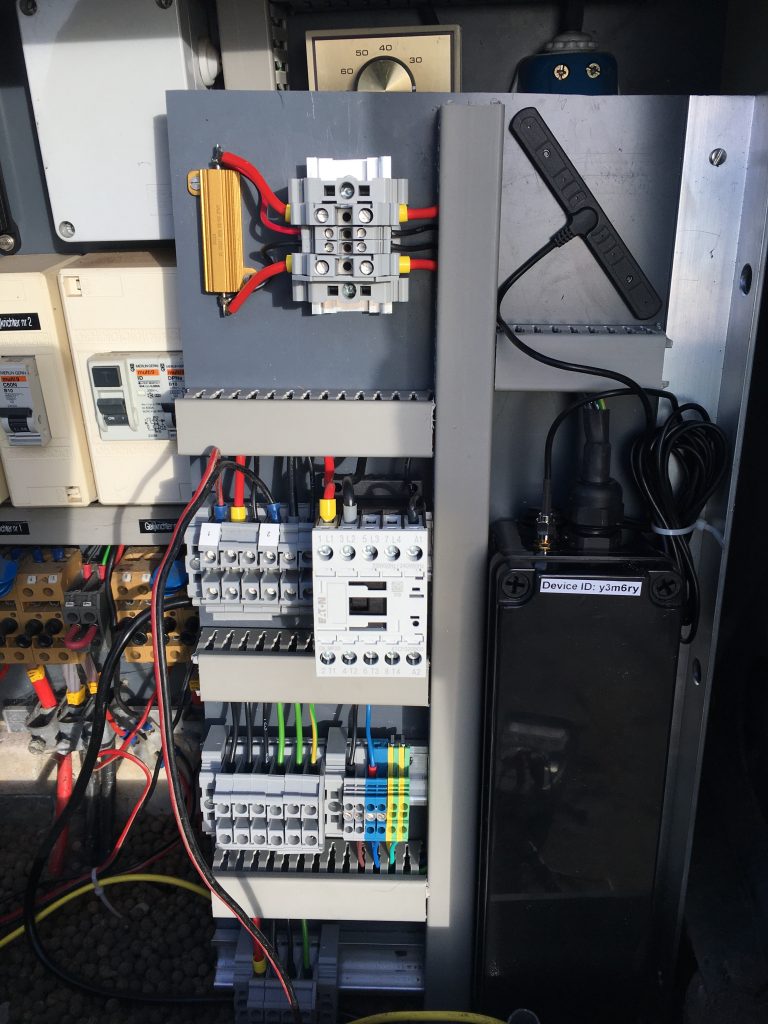

• Rectifiers: Rectifiers are read out and switched by means of an analog connection. Precise and synchronous switching is also possible through an external relay.

• Modbus connection rectifiers: For the Amstel rectifiers with a Modbus connection, a specific sensor is available. It ensures that settings in the rectifier can be adjusted remotely and that switching can be done accurately and synchronously.

• CP test stations: The Withthegrid sensors can remain in test stations and have the ability to connect to a coupon

• AC / DC drainages: In this case, The Withthegrid sensors can also reside in drains where in addition to the voltage it can measure current.

For more details, please see the technical specifications page.

Would you like to talk to one of our experts?

Get in touch!

Did this blog raise any questions? Is there something the Withthegrid team can help you with? Either click ‘learn more’ to get to know more about the team, or hit the contact us button down below!